Timber brick stone concrete metal glass and so on. All other requirements are the same. Industrial stair railing code requirements. Maximum guardrail high opening of 21 sphere Maximum guardrail low opening of 21 sphere. Industrial stair riser code requirements.

Fantastic Height should be measured vertically from the pitch line of the.

Stairs can be constructed using a wide variety of materials including. 1917120 b 2 Stair landings shall be at least 20 inches 508 cm in depth. Riser height shall be from 6 to 75 inches 1524 to 1905 cm stair width a minimum of 22 inches 5588 cm between vertical barriers tread depth a minimum of 122 inches 3048508 cm and tread nosing shall be straight leading edges. However more and more facilities and local standards call for higher IBC standards regardless. In most industrial applications with no public access to the stair system typically OSHA code will suffice. Depending on the environment and use of the stairs system they will likely need to be designed to meet either IBC or OSHA code standards.

INDUSTRIAL STAIRS Standards catalogue Product card 48 604 132 900 Industrial stairs we design and construct lightweight steel stair structures as well as integrated staircases of various design and construction that are individually designed and used in production storage and logistics halls as well as both inside and outside of industrial halls and other. All open riser is ok. Industrial stair treads code requirements. Maximum tread gap diameter of 125 IBC Stair Requirements Diagram and Chart. Standard contains specifications for the safe design and construction of fixed general industrial stairs including interior and exterior stairs around machinery tanks and other equipment and stairs leading to or from floors platforms or pits.RELATED ARTICLE :

Staggering A flight or landing on a stair or ramp should have clear headroom of at least 20m extending over the whole of the effective width.

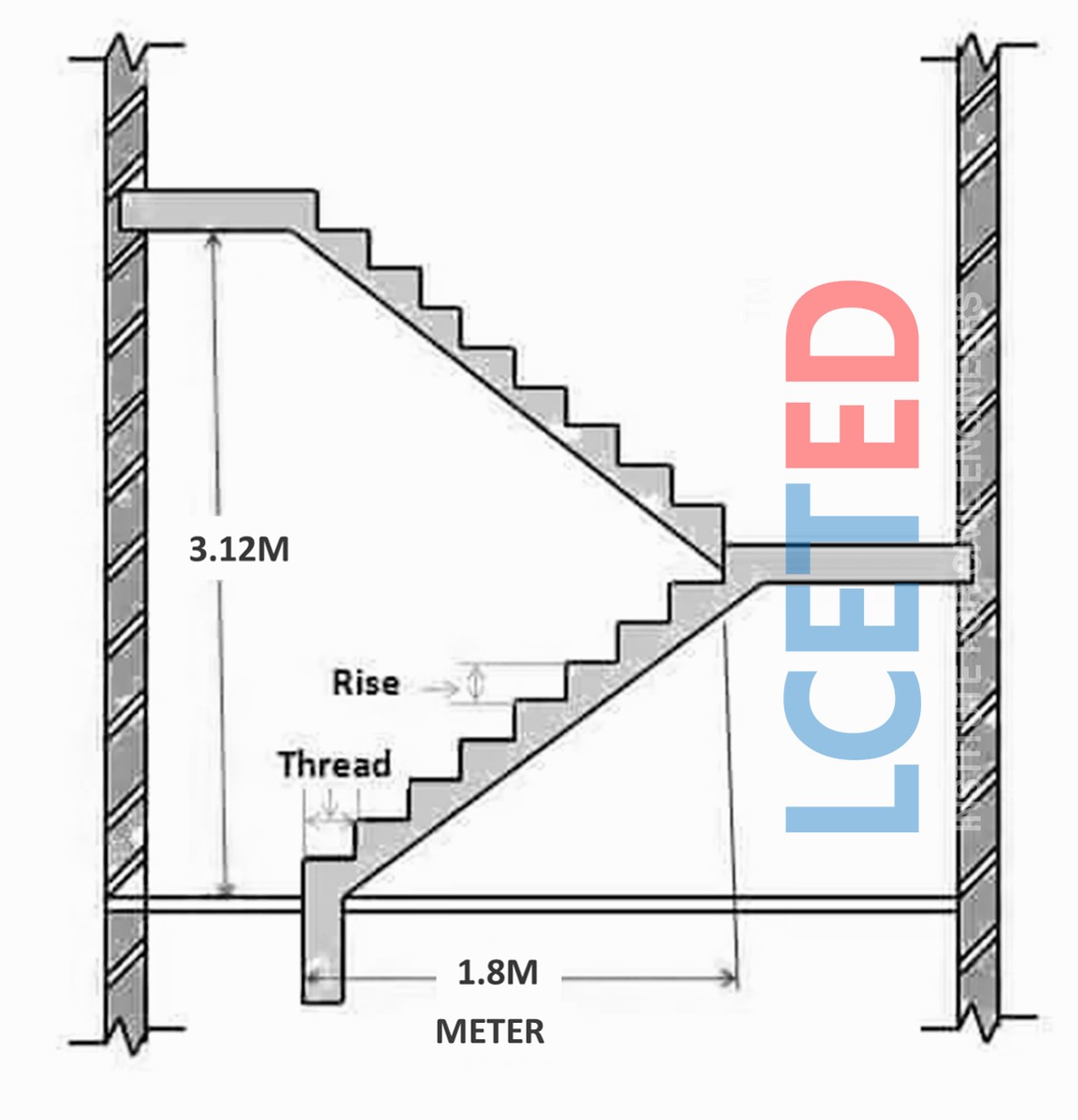

Stair Terminology The tread can be made from grating or from pans both shown in Figure 1. 191024e Angle of stairway rise. Ii BSI 26 March 2003 BS 5395-31985 1 Scope This Part of BS 5395 gives recommendations for the design of industrial type stairs walkways platforms fixed ladders and companion way ladders that are not addressed by BS EN ISO 14122 Part 1 Part 2 Part 3 and Part 4 which cover the following. BS EN ISO 14122 Safety of machinery Permanent means of access to. In a flight of stairs all steps should have the same riser and same tread.

The tread is the piece of steel that makes up the steps of the stair. Relationship between riser and tread can be shown as 2RT63cm Convention centers cinemaTheaters. R16cm Schools hospitals Office buildings R 17cm Residential Buildings R18cm Steepness of stairs. 25-36 Open riser stairs. Handrails are a support aid when using stairs.

STRUCTURAL STEEL COMPONENTS Tread. Handrails need to be easy to firmly grasp if a person loses balance. Each stairway should have at least one handrail. Stairways wider than 1000mm should have a handrail on each side. Handrails are required to.

Mental or circular stairs. Be between 900mm and 1100mm above the floor or the nosing of a stair tread. Most of our industrial stairways have a tread depth that is between 10 and 14 inches with risers between 6 and 75 inches in height to comply with OSHA standards. In addition all of our stairs are generally wider than 22 inches and come with handrails if appropriate. The depth from front to back of a tread less any overlap with the next tread above see paragraphs 11 and 12.

The top edge of the top guardrail must be 42 inches plus or minus 3 inches above. For the measurement of the going on tapered treads see. The Australian standards for stairs and landings state that you can use a maximum of 18 stairs risers in a single flight. Flights can be connected using landings. A barrier a landing 2 metres in length or a change in the direction of the stairway of 90 degrees needs to take place every 36 stairs.

191029 f 1 iii A Platform Guardrail Height. Staircases must slope at an angle of 20. OSHA set the design requirements for alternating tread stairs in section 191025 f below. 191025 f 1 Have a series of treads installed at a slope of 50 to 70 degrees from the horizontal. 191025 f 2 Have a distance between handrails of 17 to 24 inches 51 to 61 cm.

Unlike ADA guidelines the guardrails in OSHA steps also act as the handrails when the top edge of the guardrail is between 36 and 38 inches above the leading edge of the stair tread. From 30 degrees to 0 degree show for Ramps. The second is a table showing angle and type. For angles less than or equal to 30 degrees for Ramps. For angles 30 to 50 degrees for Standard Stairs.

The handrail needs to be mounted a minimum of 15 off the. For angles 50 to 70 degress for Ship Stairs. For angles 50 to 70 degrees for Alternating Tread-Type Stairs. For angles 60 to 90 degrees for Ladders. RISERS must be uniform between landings 30-50 deg 95 H.

If the handrail isnt circular it needs to have a perimeter between 4 and 625 with a maximum cross section of 225. WIDTH 22 between railings. RAILINGS open-sided stairs 44 require 1 stair railside. Open-sided stairs 44 require 1 stair rail and 1 separate handrailside. HEIGHT CLEARANCE minimum 66 clearance from nose of tread to overhead obstruction.

Where they are circular they need to be 125 to 2 in diameter. Handrails must be mounted between 34 and 38 above the tread nosings and landings. Where they are circular they need to be 125 to 2 in diameter. If the handrail isnt circular it needs to have a perimeter between 4 and 625 with a maximum cross section of 225. The handrail needs to be mounted a minimum of 15 off the.

Handrails must be mounted between 34 and 38 above the tread nosings and landings. Unlike ADA guidelines the guardrails in OSHA steps also act as the handrails when the top edge of the guardrail is between 36 and 38 inches above the leading edge of the stair tread. 191029 f 1 iii A Platform Guardrail Height. The top edge of the top guardrail must be 42 inches plus or minus 3 inches above. Mental or circular stairs.

HEIGHT CLEARANCE minimum 66 clearance from nose of tread to overhead obstruction. STRUCTURAL STEEL COMPONENTS Tread. The tread is the piece of steel that makes up the steps of the stair. Stair Terminology The tread can be made from grating or from pans both shown in Figure 1. Grating is typically used in industrial buildings while pans are usually used in commercial structures.

Open-sided stairs 44 require 1 stair rail and 1 separate handrailside. INDUSTRIAL STAIRS Standards catalogue Product card 48 604 132 900 Industrial stairs we design and construct lightweight steel stair structures as well as integrated staircases of various design and construction that are individually designed and used in production storage and logistics halls as well as both inside and outside of industrial halls and other. Depending on the environment and use of the stairs system they will likely need to be designed to meet either IBC or OSHA code standards. In most industrial applications with no public access to the stair system typically OSHA code will suffice. However more and more facilities and local standards call for higher IBC standards regardless.

RAILINGS open-sided stairs 44 require 1 stair railside. Riser height shall be from 6 to 75 inches 1524 to 1905 cm stair width a minimum of 22 inches 5588 cm between vertical barriers tread depth a minimum of 122 inches 3048508 cm and tread nosing shall be straight leading edges. 1917120 b 2 Stair landings shall be at least 20 inches 508 cm in depth. Stairs can be constructed using a wide variety of materials including. Timber brick stone concrete metal glass and so on.

WIDTH 22 between railings. RISERS must be uniform between landings 30-50 deg 95 H. For angles 60 to 90 degrees for Ladders. For angles 50 to 70 degrees for Alternating Tread-Type Stairs. For angles 50 to 70 degress for Ship Stairs. For angles 30 to 50 degrees for Standard Stairs.